The production landscape is constantly evolving, and automation is with the forefront of this transformation. especially, automatic liquid filling is revolutionizing industries by maximizing efficiency, precision, and Total productivity. Choosing the correct liquid filling equipment available for sale is essential for organizations aiming to stay competitive and meet up with the increasing calls for of the market. This article will discover the newest improvements in liquid filling devices, highlight the value of picking the appropriate maker, and supply advice on deciding on the suitable design to your unique field application.

Table of contents:

improvements in Liquid Filling devices: What Leading brands present in 2025

Why picking out the appropriate Liquid Filling device maker Impacts Your Output Quality

Liquid Filling Machine available for sale: Which Model Fits Your Industry software finest?

improvements in Liquid Filling equipment: What top companies Offer in 2025

top liquid filling device manufacturer are frequently pushing the boundaries of technology, introducing impressive attributes that greatly enhance effectiveness and efficiency. one particular key craze is The mixing of Innovative sensor technological innovation, enabling actual-time monitoring of fill degrees and automatic changes to keep up precision. Another considerable innovation is the development of much more flexible devices which can cope with a wider choice of liquid viscosities and container measurements, cutting down the necessity for numerous devices. enhanced cleaning and sterilization systems also are attaining prominence, specifically in industries with rigorous hygiene necessities. In addition, brands are incorporating smart engineering, allowing for remote monitoring, diagnostics, and predictive routine maintenance, minimizing downtime and maximizing efficiency. the usage of robotics and automation can be increasing, enabling completely automated filling traces with small human intervention. When evaluating unique equipment, take into account these improvements and choose a design that incorporates the most recent engineering to improve your generation procedures.

Why deciding on the Right Liquid Filling device producer Impacts Your Output excellent

choosing the proper liquid filling device manufacturer includes a profound impact on your output top quality. A trustworthy producer not simply delivers significant-excellent equipment but also provides knowledge, assistance, plus a commitment on your achievements. A top-tier manufacturer will do the job carefully along with you to be aware of your certain wants and propose essentially the most ideal methods. they can present custom-made device configurations to optimize your manufacturing processes and ensure dependable, accurate filling. Also, a reputable producer will supply complete coaching and technological assist to be sure your machines work smoothly and successfully. In the celebration of a problem, they'll give prompt and reliable restore companies to reduce downtime. By partnering using a dependable producer, you get access to a prosperity of data and knowledge which can help you improve your item high quality, minimize squander, and enhance your All round operational performance. It’s important to take into consideration things such as certifications and industry standing when building your conclusion.

Liquid Filling device available for purchase: Which design Fits Your Industry software very best?

acquiring the ideal liquid filling machine on the market demands very careful thing to consider of your respective certain field application. unique industries have unique needs, and The best device will range dependant upon the type of liquid staying loaded, the container dimension, and the desired creation charge.

prescription drugs: involve equipment with substantial precision, sterilization capabilities, and compliance with stringent regulatory requirements. Aseptic filling machines are often necessary.

Cosmetics: need machines that preserve aesthetic attraction and forestall spills. specific volume Management and Mild dealing with are essential.

food items and Beverage: want devices that happen to be effortless to wash and sanitize, typically necessitating stainless-steel design to satisfy hygiene needs.

Chemicals: Necessitate machines manufactured from corrosion-resistant elements and Outfitted with basic safety options to safeguard personnel.

personalized Care: get pleasure from versatile machines which will handle a variety of liquid viscosities and container styles.

prior to making a purchase, cautiously evaluate your certain requires and go with a product that may be tailor-made to the marketplace software. contemplate components including filling precision, speed, versatility, and ease of servicing.

The future of automatic filling is vibrant, with improvements constantly strengthening effectiveness and accuracy. By carefully evaluating your requirements, choosing the suitable liquid filling equipment available for purchase, and partnering which more info has a dependable liquid filling machine manufacturer, you may improve your production procedures, improve your output high quality, and realize sustained good results from the competitive Market. Embrace automation and spend money on the way forward for your company currently.

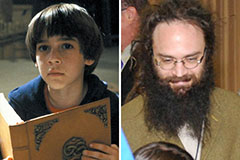

Barret Oliver Then & Now!

Barret Oliver Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Melissa Joan Hart Then & Now!

Melissa Joan Hart Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now!